This course is designed to help workers, supervisors and workplaces establish and implement a safe work procedure to unwanted electrical, hydraulic, pneumatic, kinetic and potential energy sources that cause injury or death in the workplace.

Course Content

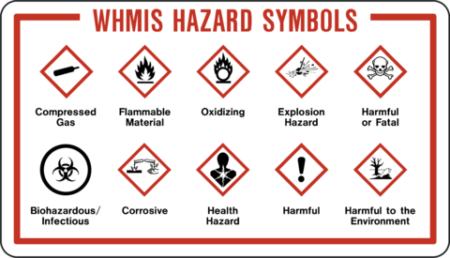

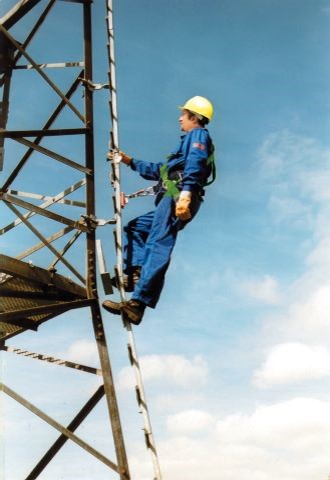

- Hazards involved with improper lockout tag out procedures

- Rights and responsibilities of all workplace parties according to the Act

- The 6-step process to lockout tag out

- Understanding energy sources

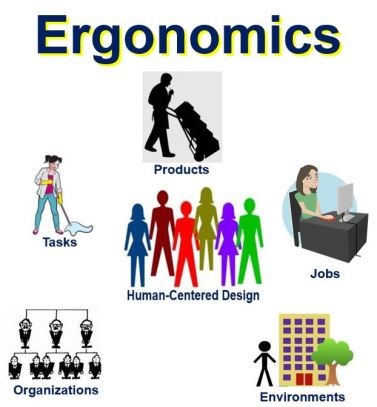

- Implementing policies and procedures

- Preparing an action plan

- Recognize, assess and control of all parties to related hazards