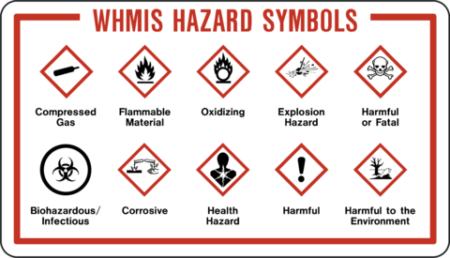

Employers have a responsibility to educate workers on the classification system that will be used in their workplace. If products will be classified according to WHMIS – GHS-2015 and new labels and SDSs provided, workers must receive WHMIS – GHS-2015 training. If products will be following WHMIS 1988 requirements, workers must be trained on the 1988 system. In most cases, workplaces will have some products that use the 2015 system and others that use the 1988 system. Those workers should receive training that provides information on both the WHMIS 1988 and the WHMIS – GHS-2015 system. Our WHMIS course has been updated to meet the training requirements needed during the transition period. It educates workers on both the WHMIS 1988 system and the new WHMIS – GHS-2015 system.

Employers have a responsibility to educate workers on the classification system that will be used in their workplace. If products will be classified according to WHMIS – GHS-2015 and new labels and SDSs provided, workers must receive WHMIS – GHS-2015 training. If products will be following WHMIS 1988 requirements, workers must be trained on the 1988 system. In most cases, workplaces will have some products that use the 2015 system and others that use the 1988 system. Those workers should receive training that provides information on both the WHMIS 1988 and the WHMIS – GHS-2015 system. Our WHMIS course has been updated to meet the training requirements needed during the transition period. It educates workers on both the WHMIS 1988 system and the new WHMIS – GHS-2015 system.

Bill-168 Training

Our Bill-168 course covers all legislative requirements according to the Occupational Health and Safety Act. It is designed to assist companies, supervisors and workers with the knowledge and understanding of their rights and responsibilities. Course Content- Duties and responsibilities according to the Act

- Rights and due diligence according to legislation

- Reporting

- Case study discussions

Our fire safety/extinguisher course teaches participants and workplaces about the legislated fire safety responsibilities of the employer and the worker. We will discuss safe work practices related to fire prevention and provides practical information about emergency response in situations involving fire.

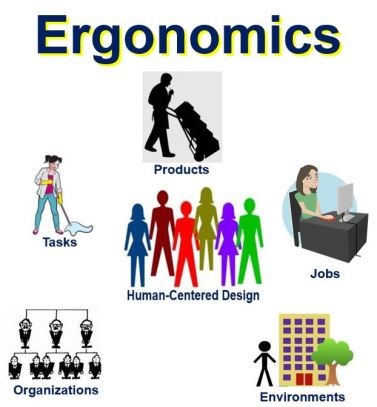

Our fire safety/extinguisher course teaches participants and workplaces about the legislated fire safety responsibilities of the employer and the worker. We will discuss safe work practices related to fire prevention and provides practical information about emergency response in situations involving fire. Our interactive Ergonomics course is designed for participants to understand the science of ergonomics, minimize injuries due to chronic physical and psychological stresses while maximizing productivity and efficiency. Reducing injuries thus reduces worker’s compensation claims in this area which in turn reduces the agency’s premiums. The visible cost is estimated to be 15 to 20 billion dollars a year in worker’s compensation costs. Reducing the injuries reduces those visible costs but also the invisible costs. These include absenteeism, loss of productivity, rework, lower morale, turnover, other employees having to complete absent employees’ tasks. recognize, substitute and eliminate.

Our interactive Ergonomics course is designed for participants to understand the science of ergonomics, minimize injuries due to chronic physical and psychological stresses while maximizing productivity and efficiency. Reducing injuries thus reduces worker’s compensation claims in this area which in turn reduces the agency’s premiums. The visible cost is estimated to be 15 to 20 billion dollars a year in worker’s compensation costs. Reducing the injuries reduces those visible costs but also the invisible costs. These include absenteeism, loss of productivity, rework, lower morale, turnover, other employees having to complete absent employees’ tasks. recognize, substitute and eliminate.

This course is designed to help workers, supervisors and workplaces establish and implement a safe work procedure to unwanted electrical, hydraulic, pneumatic, kinetic and potential energy sources that cause injury or death in the workplace.

Course Content

- Hazards involved with improper lockout tag out procedures

- Rights and responsibilities of all workplace parties according to the Act

- The 6-step process to lockout tag out

- Understanding energy sources

- Implementing policies and procedures

- Preparing an action plan

- Recognize, assess and control of all parties to related hazards

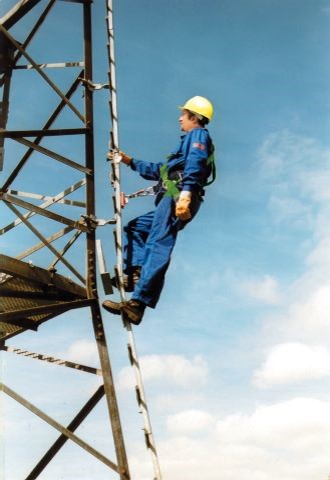

At C&R Safety Training Solutions, our Aerial/Elevated Work Platform Safety Course provides our participants with the knowledge and understanding of the safe operation and MOL standards, system components and protection systems. Approximately 20% of all lost time injuries can be contributed to falls in the workplace. Most injuries are same level, others are lower level. Ladders contribute to the more serious injuries or death. In fact, only motor vehicles contribute to a higher risk of workplace fatalities. You may have never personally experienced a fall from an Aerial Work Platform to the ground but that doesn’t mean that hazards don’t exist; less frequent hazards mean the hazard is hidden and makes it more dangerous. It’s imperative that workers understand the hazards involved when working at heights and consistently follow the rules and safety work procedures.

At C&R Safety Training Solutions, our Aerial/Elevated Work Platform Safety Course provides our participants with the knowledge and understanding of the safe operation and MOL standards, system components and protection systems. Approximately 20% of all lost time injuries can be contributed to falls in the workplace. Most injuries are same level, others are lower level. Ladders contribute to the more serious injuries or death. In fact, only motor vehicles contribute to a higher risk of workplace fatalities. You may have never personally experienced a fall from an Aerial Work Platform to the ground but that doesn’t mean that hazards don’t exist; less frequent hazards mean the hazard is hidden and makes it more dangerous. It’s imperative that workers understand the hazards involved when working at heights and consistently follow the rules and safety work procedures. Our Working at Heights Safety Protection Awareness Program is an approved CPO course and provides our participants with the knowledge and understanding of working at heights basics, system components and protection systems according to the Ministry of Labour Regulations and Standards. Approximately 20% of all lost time injuries can be contributed to falls in the workplace. Most injuries are same level, others are lower level. Ladders contribute to the more serious injuries or death. In fact, only motor vehicles contribute to a higher risk of workplace fatalities. You may have never personally experienced a fall to a lower level but that doesn’t mean that hazards don’t exist; less frequent hazards mean hazard is hidden and makes it more dangerous. It’s imperative that workers understand the hazards involved when working at heights and consistently follow the rules and safety work procedures.

Our Working at Heights Safety Protection Awareness Program is an approved CPO course and provides our participants with the knowledge and understanding of working at heights basics, system components and protection systems according to the Ministry of Labour Regulations and Standards. Approximately 20% of all lost time injuries can be contributed to falls in the workplace. Most injuries are same level, others are lower level. Ladders contribute to the more serious injuries or death. In fact, only motor vehicles contribute to a higher risk of workplace fatalities. You may have never personally experienced a fall to a lower level but that doesn’t mean that hazards don’t exist; less frequent hazards mean hazard is hidden and makes it more dangerous. It’s imperative that workers understand the hazards involved when working at heights and consistently follow the rules and safety work procedures. This course provides workers with the basic fall prevention information they require to work safely in areas where they may be exposed to fall hazards. Participants receive the most up-to-date information with hands-on instruction from industry experts and trained adult educators who are experienced in working at heights.

This course provides workers with the basic fall prevention information they require to work safely in areas where they may be exposed to fall hazards. Participants receive the most up-to-date information with hands-on instruction from industry experts and trained adult educators who are experienced in working at heights. At C&R Safety Training Solutions we offer a certified Power Tool Safety and Hazard Prevention Training. Power tools and equipment, both stationary and portable (hand-held), are commonly used in several industries. We have resources on working safely with many types of power tools, including chainsaws, circular saws, grinders, nail guns, and more.

At C&R Safety Training Solutions we offer a certified Power Tool Safety and Hazard Prevention Training. Power tools and equipment, both stationary and portable (hand-held), are commonly used in several industries. We have resources on working safely with many types of power tools, including chainsaws, circular saws, grinders, nail guns, and more. At C&R Safety Training Solutions, our training program is for persons operating any mobile crane with a lifting capacity of 0 to 8 tons including any of the following crane types: articulating (knuckle) boom, telescoping boom, radial boom derricks (RBDs), sign erectors, or carry deck industrial-type cranes.

At C&R Safety Training Solutions, our training program is for persons operating any mobile crane with a lifting capacity of 0 to 8 tons including any of the following crane types: articulating (knuckle) boom, telescoping boom, radial boom derricks (RBDs), sign erectors, or carry deck industrial-type cranes. Our program at C&R Safety Training Solutions is designed for persons operating heavy equipment in on-site specific workplaces. The training will cover a combination of on-the-job and classroom training. The operator/trainee must pass the classroom training and written test as well as pass a demonstration of skills such as operating a front-end loader, backhoe, excavator, bulldozer, skid-steer and crawlers on-site demonstrating a pre-equipment inspection, start-up procedures, safe operation, and shut down procedures.

Our program at C&R Safety Training Solutions is designed for persons operating heavy equipment in on-site specific workplaces. The training will cover a combination of on-the-job and classroom training. The operator/trainee must pass the classroom training and written test as well as pass a demonstration of skills such as operating a front-end loader, backhoe, excavator, bulldozer, skid-steer and crawlers on-site demonstrating a pre-equipment inspection, start-up procedures, safe operation, and shut down procedures. This program is designed to provide the participants with in-class learning with a site-specific practical training component. Upon completion, participants will be knowledgeable about confined space entry requirements under the Occupational Health and Safety Act, and will be able to recognize confined spaces, describe the major hazards, identify controls, and perform a confined space rescue.

This program is designed to provide the participants with in-class learning with a site-specific practical training component. Upon completion, participants will be knowledgeable about confined space entry requirements under the Occupational Health and Safety Act, and will be able to recognize confined spaces, describe the major hazards, identify controls, and perform a confined space rescue. Our program is designed for persons operating a skid-steer in the workplace. The training will cover a combination of on-the-job and classroom training. The operator/trainee must pass the classroom training and written test as well as pass a demonstration of skills such as operating the skid-steer on-site demonstrating a pre-equipment inspection, start-up procedures, safe operation, and shut down procedures.

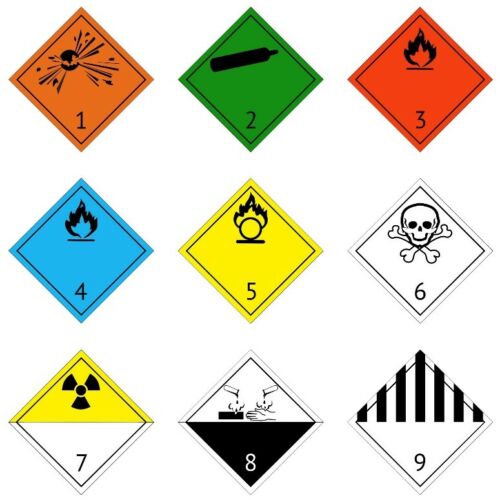

Our program is designed for persons operating a skid-steer in the workplace. The training will cover a combination of on-the-job and classroom training. The operator/trainee must pass the classroom training and written test as well as pass a demonstration of skills such as operating the skid-steer on-site demonstrating a pre-equipment inspection, start-up procedures, safe operation, and shut down procedures. This program will teach participants their legal responsibilities for safe handling, storing, and transporting of the nine classes of dangerous goods. Participants are provided with an overview of the Dangerous Goods Act and related regulations. The participants will understand their duties and responsibilities according to the Ministry of Transportation Act and Ministry of Labour guidelines. Along with the understanding of UN numbers.

This program will teach participants their legal responsibilities for safe handling, storing, and transporting of the nine classes of dangerous goods. Participants are provided with an overview of the Dangerous Goods Act and related regulations. The participants will understand their duties and responsibilities according to the Ministry of Transportation Act and Ministry of Labour guidelines. Along with the understanding of UN numbers. Our program covers the specific hazards related to the use of propane in everyday use. For example; forklifts, torches, BBQ’s, heaters, small stoves, and much more applications. It provides participants with information on how to safely connect, disconnect, and the activation of propane equipment in the workplace.

Our program covers the specific hazards related to the use of propane in everyday use. For example; forklifts, torches, BBQ’s, heaters, small stoves, and much more applications. It provides participants with information on how to safely connect, disconnect, and the activation of propane equipment in the workplace. Forklift Classes 1 – 5 Here at C&R Safety Training Solutions we offer a one-day interactive safe forklift operation course according to Ministry of Labour standards, guidelines and regulations on the principles of:

Forklift Classes 1 – 5 Here at C&R Safety Training Solutions we offer a one-day interactive safe forklift operation course according to Ministry of Labour standards, guidelines and regulations on the principles of:- Understanding the limitations that affect truck stability and safe loading criteria

- Understanding the fundamentals of handling high-risk loads

- Knowing the legal responsibilities associated with lift trucks

- Understanding the legal standards set out in the Occupational Health and Safety Act

- Hazard recognition in advance situational risks in and around the lift truck

Forklift Class 7 – Rough Terrain

Here at C&R Safety Training Solutions we offer a one-day interactive safe Rough Terrain forklift operation course according to Ministry of Labour standards, guidelines and regulations on the principles of:

- Understanding the limitations that affect truck stability and safe loading criteria

- Understanding the fundamentals of handling high-risk loads

- Knowing the legal responsibilities associated with lift trucks

- Understanding the legal standards set out in the Occupational Health and Safety Act

- Hazard recognition in advance situational risks in and around the rough terrain lift truck

- Hazards associated with the telescopic boom

Forklift Class 7 (Propane) – Rough Terrain

Here at C&R Safety Training Solutions we offer a one-day interactive safe Rough Terrain forklift operation course according to Ministry of Labour standards, guidelines and regulations on the principles of:

- Understanding the limitations that affect truck stability and safe loading criteria

- Understanding the fundamentals of handling high-risk loads

- Knowing the legal responsibilities associated with lift trucks

- Understanding the legal standards set out in the Occupational Health and Safety Act

- Hazard recognition in advance situational risks in and around the rough terrain lift truck

- Hazards associated with the telescopic boom

At C&R Safety Training Solutions we are committed to the health and safety of everyone involved we it comes to moving large and heavy equipment and materials when hoisting. In many industries, when the movement of a large object is required, a crane is brought in to help lift the load. In many ways, cranes are helpful and convenient pieces of equipment. But we can’t forget that cranes are also dangerous, especially when the load they will be carrying has not been rigged properly.

At C&R Safety Training Solutions we are committed to the health and safety of everyone involved we it comes to moving large and heavy equipment and materials when hoisting. In many industries, when the movement of a large object is required, a crane is brought in to help lift the load. In many ways, cranes are helpful and convenient pieces of equipment. But we can’t forget that cranes are also dangerous, especially when the load they will be carrying has not been rigged properly. Our program is designed for persons operating a front-end loader in the workplace. The training will cover a combination of on-the-job and classroom training. The operator/trainee must pass the classroom training and written test as well as pass a demonstration of skills such as operating the front-end loader on-site demonstrating a pre-equipment inspection, start-up procedures, safe operation, and shut down procedures.

Our program is designed for persons operating a front-end loader in the workplace. The training will cover a combination of on-the-job and classroom training. The operator/trainee must pass the classroom training and written test as well as pass a demonstration of skills such as operating the front-end loader on-site demonstrating a pre-equipment inspection, start-up procedures, safe operation, and shut down procedures. Our program covers the specific hazards related to the use of propane in roofing applications. It provides participants with information on how to safely connect, disconnect, and the activation of propane torches and kettles in accordance with Technical Standards and Safety Authority (TSSA) requirements.

Our program covers the specific hazards related to the use of propane in roofing applications. It provides participants with information on how to safely connect, disconnect, and the activation of propane torches and kettles in accordance with Technical Standards and Safety Authority (TSSA) requirements. C&R Safety Training Solutions offers a half-day course on machine guarding. When machines are not properly guarded or locked out during maintenance, repair and other activities at industrial sector workplaces, workers can be exposed to several hazards. These hazards can result in serious injuries such as amputations of limbs or death. Hazards can include:

C&R Safety Training Solutions offers a half-day course on machine guarding. When machines are not properly guarded or locked out during maintenance, repair and other activities at industrial sector workplaces, workers can be exposed to several hazards. These hazards can result in serious injuries such as amputations of limbs or death. Hazards can include:- Exposure to in-running nip hazards, i.e. getting caught up in machinery and moving parts if equipment is not properly guarded.

- Exposure to hazardous motion, such as rotating machine parts, if equipment is not properly locked and blocked during maintenance and repair.

Chainsaw Safety Training provides users with the knowledge and understanding of operating a chainsaw, proper use of personal protective equipment, maintenance and understanding felling, Limbing and bucking procedures. These techniques are based around and follow the Ministry of Labour (MOL) guidelines.

Chainsaw Safety Training provides users with the knowledge and understanding of operating a chainsaw, proper use of personal protective equipment, maintenance and understanding felling, Limbing and bucking procedures. These techniques are based around and follow the Ministry of Labour (MOL) guidelines. Forklift Classes 1 – 5 Here at C&R Safety Training Solutions we offer a one-day interactive safe forklift operation course according to Ministry of Labour standards, guidelines and regulations on the principles of:

Forklift Classes 1 – 5 Here at C&R Safety Training Solutions we offer a one-day interactive safe forklift operation course according to Ministry of Labour standards, guidelines and regulations on the principles of:- Understanding the limitations that affect truck stability and safe loading criteria

- Understanding the fundamentals of handling high-risk loads

- Knowing the legal responsibilities associated with lift trucks

- Understanding the legal standards set out in the Occupational Health and Safety Act

- Hazard recognition in advance situational risks in and around the lift truck

- Sale!

This program designed to assists those responsible for controlling traffic and creating, implementing, and/or overseeing the safety of the construction zone. Participants are taught safe practices when it comes to controlling vehicles, pedestrians and worker safety.

This program designed to assists those responsible for controlling traffic and creating, implementing, and/or overseeing the safety of the construction zone. Participants are taught safe practices when it comes to controlling vehicles, pedestrians and worker safety.  Our Ladder Safety course provides users with the knowledge and understanding of all the different types of “ladders” and how to use the appropriate ladder for a specific task. Nearly 20% of all lost time injuries (time lost for the worker) can be contributed to falls in the workplace. The majority of injuries are same level, others are lower level. Ladders contribute to the more serious injuries or death. In fact, only motor vehicles contribute to a higher risk of workplace validities. You may have never personally experienced a fall but that doesn’t mean that hazards don’t exist; It’s imperative that worker know the hazards working with “ladders” and consistently follows rules and safety work procedures and don’t become another statistic.

Our Ladder Safety course provides users with the knowledge and understanding of all the different types of “ladders” and how to use the appropriate ladder for a specific task. Nearly 20% of all lost time injuries (time lost for the worker) can be contributed to falls in the workplace. The majority of injuries are same level, others are lower level. Ladders contribute to the more serious injuries or death. In fact, only motor vehicles contribute to a higher risk of workplace validities. You may have never personally experienced a fall but that doesn’t mean that hazards don’t exist; It’s imperative that worker know the hazards working with “ladders” and consistently follows rules and safety work procedures and don’t become another statistic. At C&R Safety Training Solutions, our Class III Forklift Safety Course provides our participants with the knowledge and understanding of the safe operation and MOL standards, system components and protection systems. Here at C&R Safety Training Solutions we offer a half day interactive safe forklift operation course according to Ministry of Labour standards, guidelines and regulations on the principles.

At C&R Safety Training Solutions, our Class III Forklift Safety Course provides our participants with the knowledge and understanding of the safe operation and MOL standards, system components and protection systems. Here at C&R Safety Training Solutions we offer a half day interactive safe forklift operation course according to Ministry of Labour standards, guidelines and regulations on the principles. At C&R Safety Training Solutions we are dedicated to safe workplace injuries and prevention. Our interactive Sharps Training includes a PowerPoint presentation and a hands-on portion for the safe handling of needles, with and without the syringe, e.g. butterfly needles, vacutainer needles, scalpel and razor blades, microscope slides and covers, glass capillary tubes, Pasteur’s pipettes, pipette man tips, sharp, pointy scissors, microtome knives, any broken glass or plastic lab-ware with sharp edges.

At C&R Safety Training Solutions we are dedicated to safe workplace injuries and prevention. Our interactive Sharps Training includes a PowerPoint presentation and a hands-on portion for the safe handling of needles, with and without the syringe, e.g. butterfly needles, vacutainer needles, scalpel and razor blades, microscope slides and covers, glass capillary tubes, Pasteur’s pipettes, pipette man tips, sharp, pointy scissors, microtome knives, any broken glass or plastic lab-ware with sharp edges.

At C&R Safety Training Solutions we are dedicated to safe workplace injuries and prevention. Our interactive Sharps Training includes a PowerPoint presentation and a hands-on portion for the safe handling of needles, with and without the syringe, e.g. butterfly needles, vacutainer needles, scalpel and razor blades, microscope slides and covers, glass capillary tubes, Pasteur’s pipettes, pipette man tips, sharp, pointy scissors, microtome knives, any broken glass or plastic lab-ware with sharp edges.

At C&R Safety Training Solutions we are dedicated to safe workplace injuries and prevention. Our interactive Sharps Training includes a PowerPoint presentation and a hands-on portion for the safe handling of needles, with and without the syringe, e.g. butterfly needles, vacutainer needles, scalpel and razor blades, microscope slides and covers, glass capillary tubes, Pasteur’s pipettes, pipette man tips, sharp, pointy scissors, microtome knives, any broken glass or plastic lab-ware with sharp edges.

Our half-day Scaffolding Safety and Hazard Awareness program is designed to assist those who work on or near scaffolds to understand Ministry of Labour legislation, understand the risks associated with their work, and find out how to manage those risks.

This program will assist participants through a power point presentation and open discussion, case studies as well as an actual incident report, an inspection form requirement, evaluation plan and rescue procedures. Participants will develop a better understanding of their roles and responsibilities according to the OHSA as scaffold users and learn a variety of ways to recognize and control hazards in their work. C&R Safety Training Solutions is dedicated to your Health & Safety, our Lead Hazard Awareness course is designed to educate the learner in the awareness of working around lead. Lead is one of the most common toxic elements found in industry and is a leading cause of workplace illness. According to the Centers for Disease Control & Prevention, despite improvements in public health policies and substantial reductions in blood lead levels (BLLs) in adults, lead exposure remains an important health problem worldwide. Nearly every construction trade has the opportunity for potential exposure to lead during “normal” construction tasks including carpenters, electricians, ironworkers, painters, plumbers, sheet metal workers, among others.

C&R Safety Training Solutions is dedicated to your Health & Safety, our Lead Hazard Awareness course is designed to educate the learner in the awareness of working around lead. Lead is one of the most common toxic elements found in industry and is a leading cause of workplace illness. According to the Centers for Disease Control & Prevention, despite improvements in public health policies and substantial reductions in blood lead levels (BLLs) in adults, lead exposure remains an important health problem worldwide. Nearly every construction trade has the opportunity for potential exposure to lead during “normal” construction tasks including carpenters, electricians, ironworkers, painters, plumbers, sheet metal workers, among others. At C&R Safety Training Solutions, our Asbestos Awareness Program provides our participants with the knowledge and understanding when working with Asbestos. This course will guide you through all aspects of Asbestos, from the hazards that are associated with Asbestos to how to protect yourself with safe work practices. Our comprehensive course will explain in detail what you need to know and emphasize key points. The course has been designed to meet and exceed Occupational Health and Safety Guidelines, so by completing this course, you can improve your knowledge of an important part of workplace safety. It’s imperative that workers understand the hazards involved when working with Asbestos and consistently follow the rules and safety work procedures.

At C&R Safety Training Solutions, our Asbestos Awareness Program provides our participants with the knowledge and understanding when working with Asbestos. This course will guide you through all aspects of Asbestos, from the hazards that are associated with Asbestos to how to protect yourself with safe work practices. Our comprehensive course will explain in detail what you need to know and emphasize key points. The course has been designed to meet and exceed Occupational Health and Safety Guidelines, so by completing this course, you can improve your knowledge of an important part of workplace safety. It’s imperative that workers understand the hazards involved when working with Asbestos and consistently follow the rules and safety work procedures.